|

Name

|

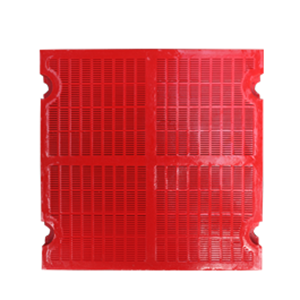

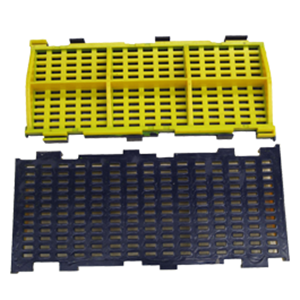

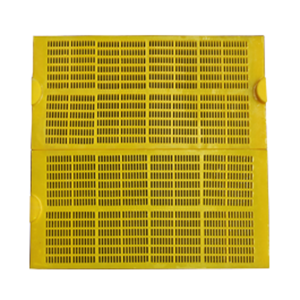

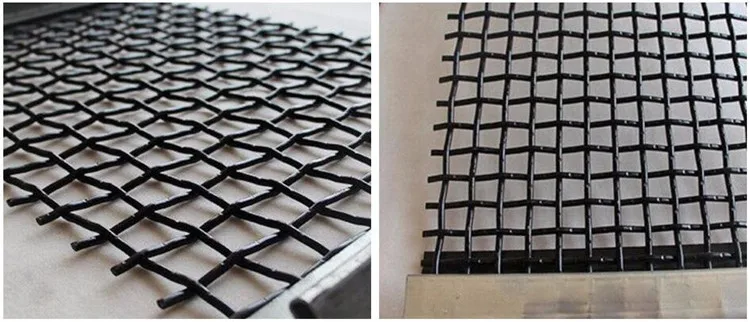

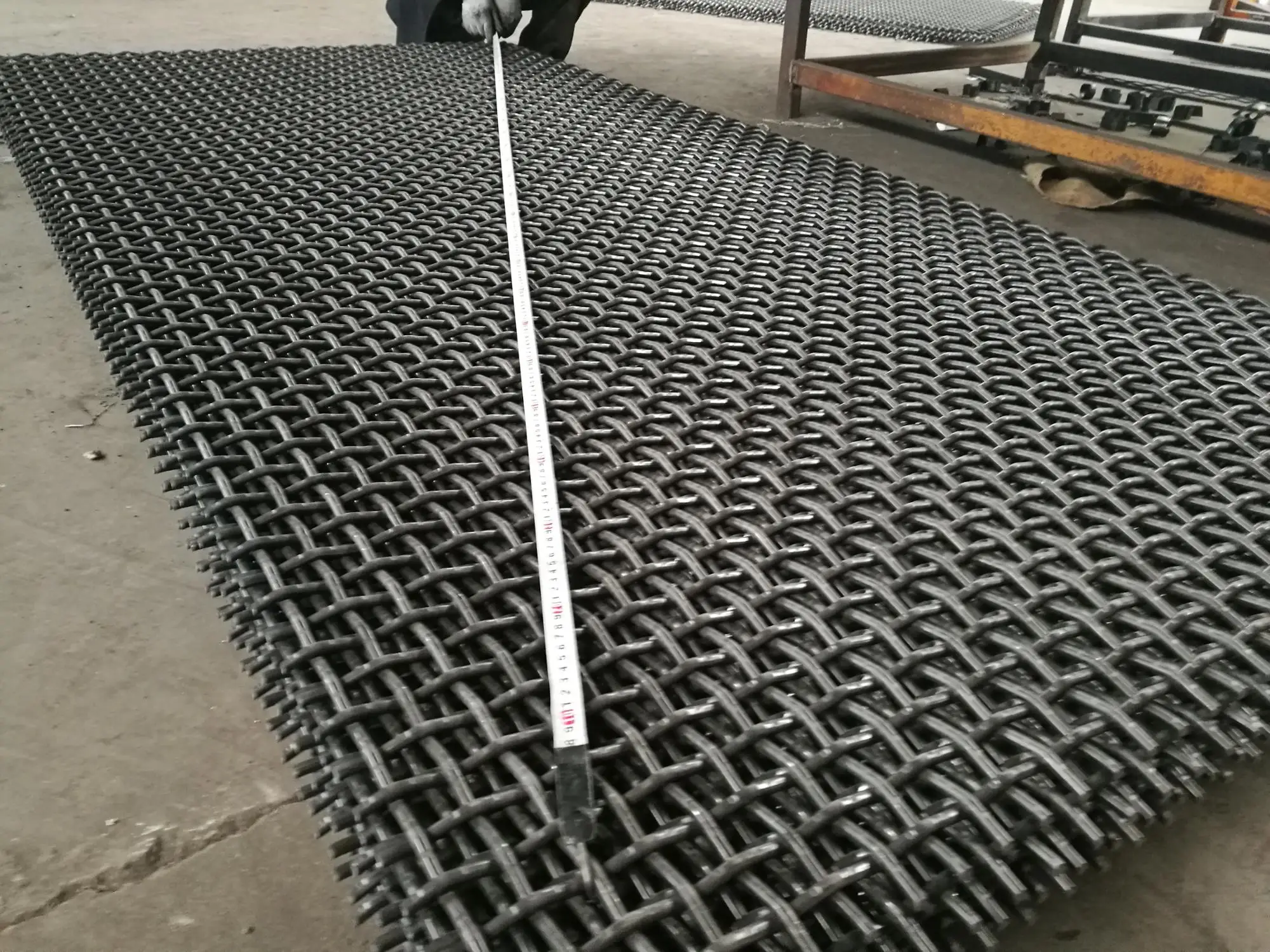

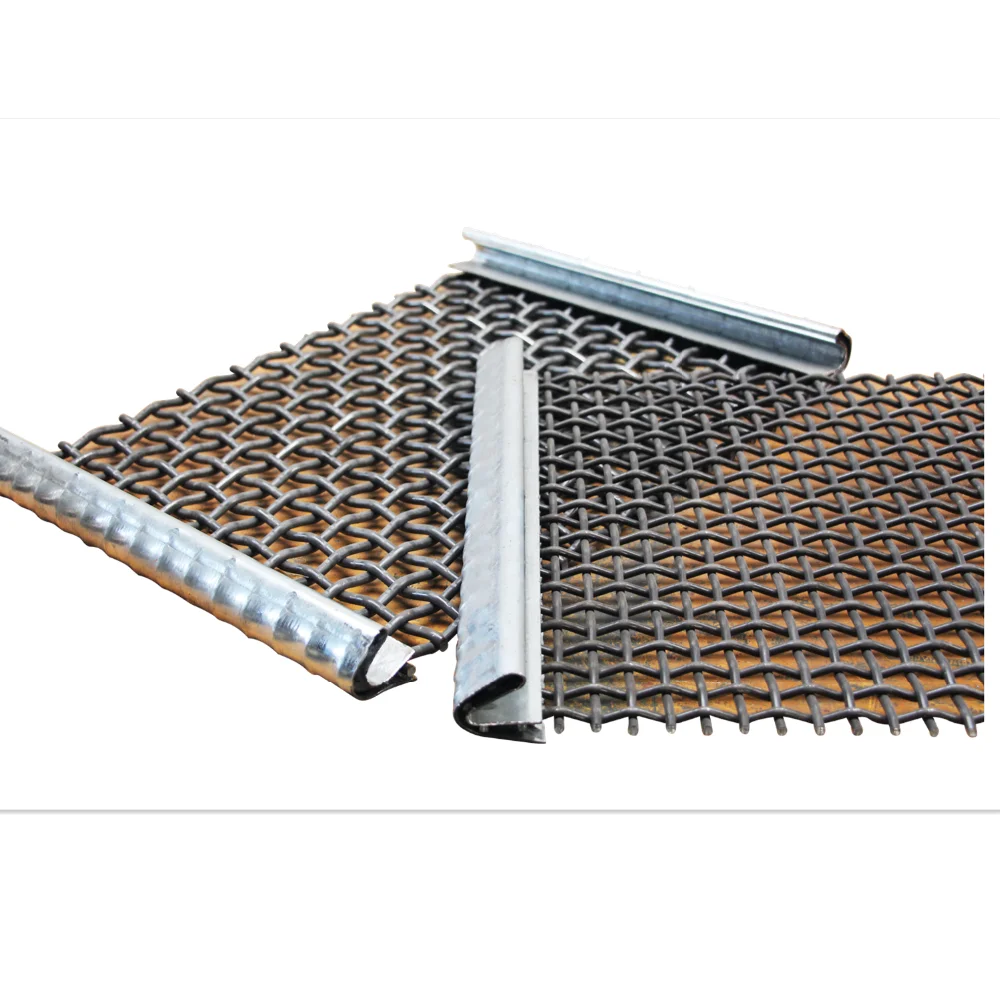

Vibrating Screen Mesh

|

|

High carbon steel:

|

65Mn,45#,50#,55#,60#,70#,,72A

|

|

Wire diameter

|

0.8mm-12.7mm,Our finished wire is inspected by third party SGS,Tolerance+_0.03mm .

|

|

Aperture/Opening

|

2mm to 100mm,tolerance +-3%

|

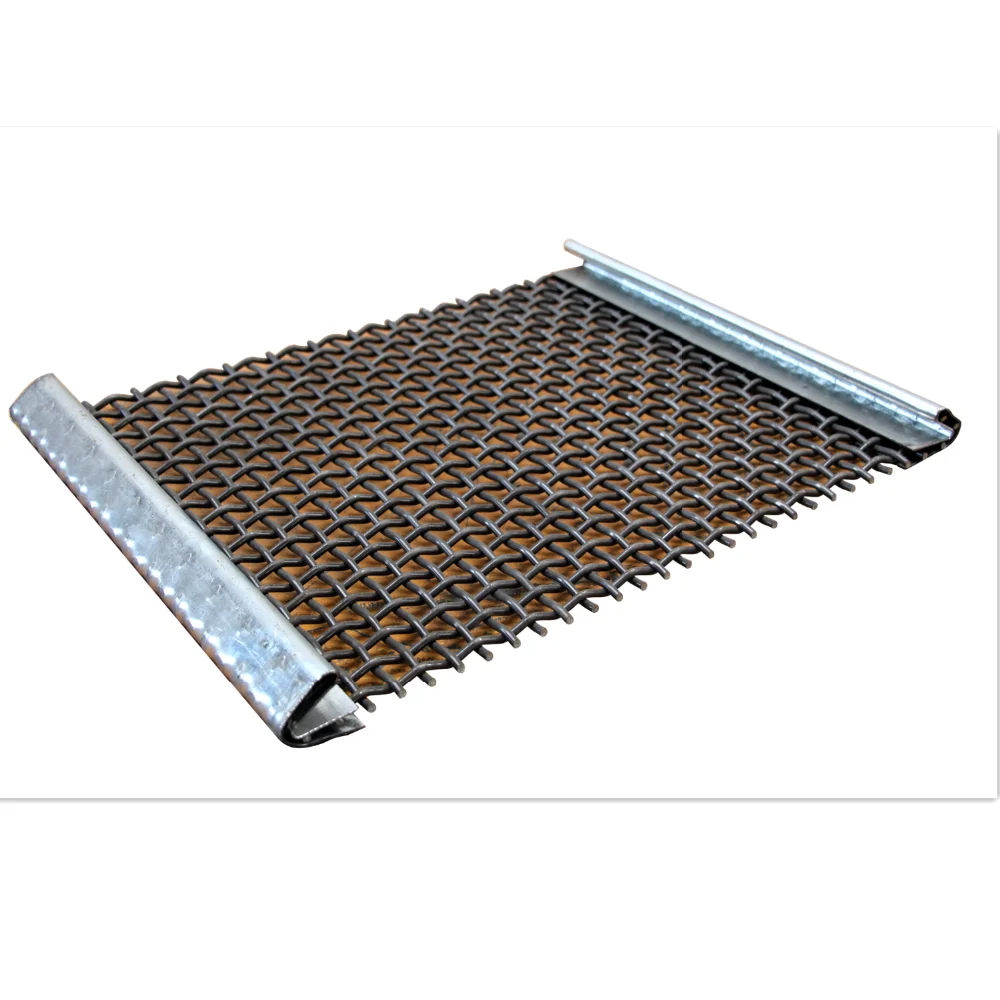

Weaving style:

Plain weave Double crimped Intermediate crimped Flat top crimped

Features:

1.No tearing and abrasion 2.Placed above rubber beads to avoid metal to metal contact

3.Corrosion resistance 4. High temperature resistance

IMPORTANT FACTS TO CONSIDER WHEN ORDERING SCREENS:

When screens form part of the manufacturing process, the profits will depend on the specification of the screens which must be chosen to give optimum performance. The specification of the screen best suited to the screening operation depends on:

The screen selected must achieve a compromise amongst these factors.

When ordering screens the following technical aspects should be taken into account :

Thickness of wire

Thick wire will last longer than thin wire, but will give a smaller open area and will therefore pass less material per unit area.

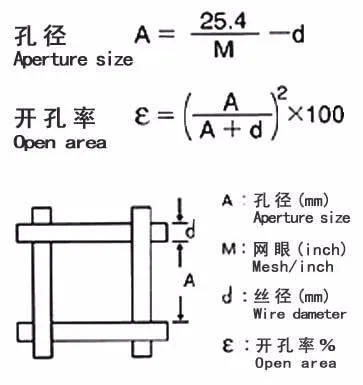

Open Area

This is the most important factor in obtaining maximum output. The larger the open area the less screen is wasted and the faster the speed of screening. This open area factor must balanced against the wire diameter to give adequate life

Mesh

The mesh refers to the number of openings per inch. The mesh is counted by starting from the centre of one wire and counting the number of opening to a point one inch away.

OEM/ODM Accept the following types of customization with Polyurethane collocation

Aperture or Opening Width

This is the actual opening between the wires , and is also referred to as space. Thus 10mm aperture , 4mm wire ,means the wires are 10mm apart , and the diameter of wire is 4mm

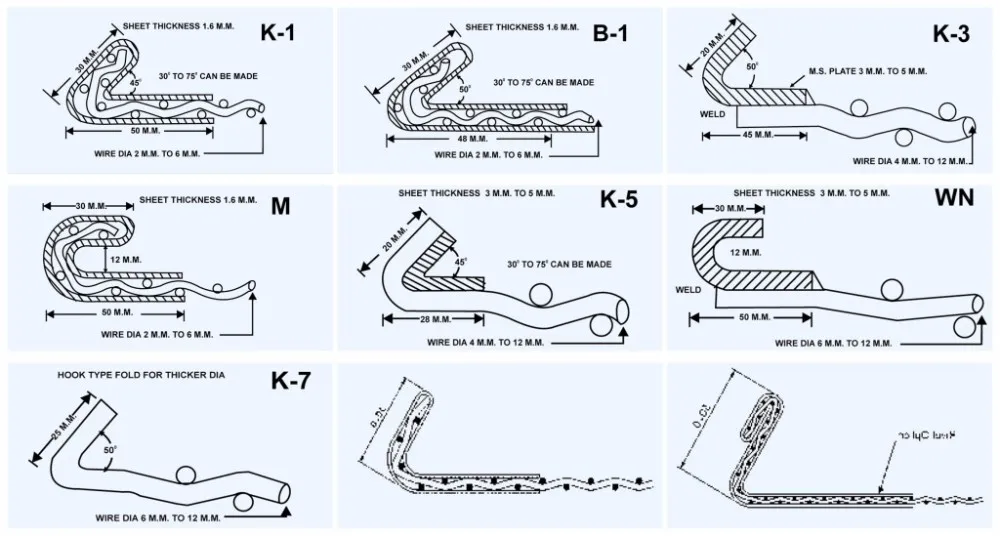

Pre –Crimped Wire Screens

( Wire Crimped before weaving )

These are generally used for 10 mesh and coarser . Pre –crimped wire screens have very accurate opening and are tightly woven. The wires have very little movement, resulting in:

Pre-crimped wire screens are generally preferred when accurate sizing is important and for vibrating screens where tightness is important.

Hooks and Hooks Strips on Vibrating Screens

Stainless parameters

|

NO

|

Grade

|

chemical Composition

|

|||

|

C

|

Ni

|

Mn

|

Cr

|

||

|

1

|

304

|

≤0.08

|

8.0-11.0

|

≤2.0

|

18.0-20.0

|

|

2

|

321

|

≤0.08

|

9.0-12.0

|

≤2.0

|

17.0-19.0

|

|

3

|

316

|

≤0.08

|

10.0-14.0

|

≤2.0

|

16.0-18.5

|

|

4

|

2205

|

≤0.03

|

4.5-6.5

|

2.5-3.5

|

21.0-24.0

|

|

5

|

2507

|

≤0.03

|

6-8

|

≤1.2

|

24-26

|

Carbon steel parameter:

|

NO

|

Grade

|

chemical Composition

|

||

|

C

|

Si

|

Mn

|

||

|

1

|

45

|

0.42-0.50

|

0.17-0.37

|

0.50-0.80

|

|

2

|

50

|

0.47-0.55

|

||

|

3

|

55

|

0.52-0.60

|

||

|

4

|

60

|

0.57-0.65

|

||

|

5

|

65

|

0.62-0.70

|

||

|

6

|

70

|

0.67-0.75

|

||

|

7

|

65Mn

|

0.62-0.70

|

0.90-1.20

|

|

|

8

|

72A

|

0.70-0.75

|

0.15-0.35

|

0.30-0.60

|