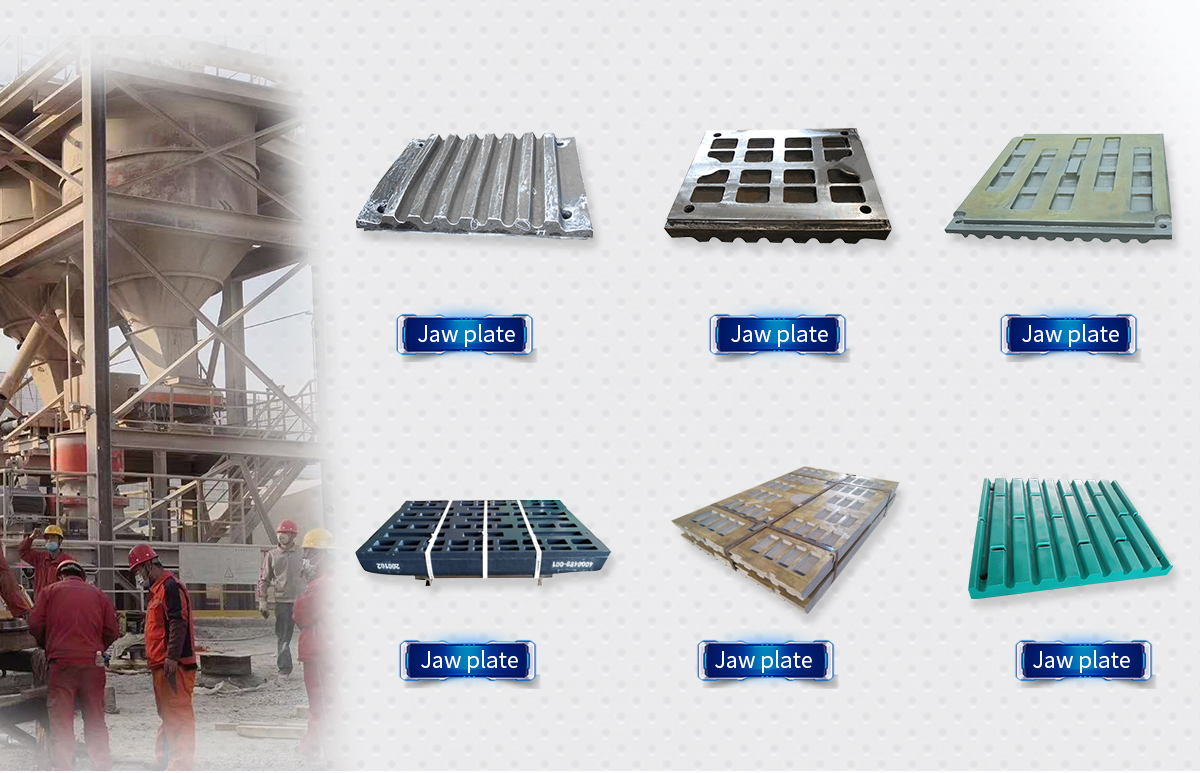

Introduction:Jaw plate is the main wear part of jaw crusher, which is divided into moving jaw plate and fixed jaw plate TOUGHING’s jaw plate and cheek plate is manufactured with high manganese steel of Manganese 13%-30% to meet all kinds of requirement from clients. Through the special heat-treatment process, our jaw plate has stronger wear-resistant and the service life 10% longer than those made of traditional high manganese steel. According to the feedback from customers, the good performance of our jaw plate in different working condition greatly decreased the time of repair and the use-cost, and help client Improving comprehensive economic benefits.

Categories: Jaw Crusher Wear Spare Parts, Jaw PlateTags: Fixed Jaw Plate, Jaw Crusher Wear Spare Parts, Jaw plate, Movable Jaw Plate