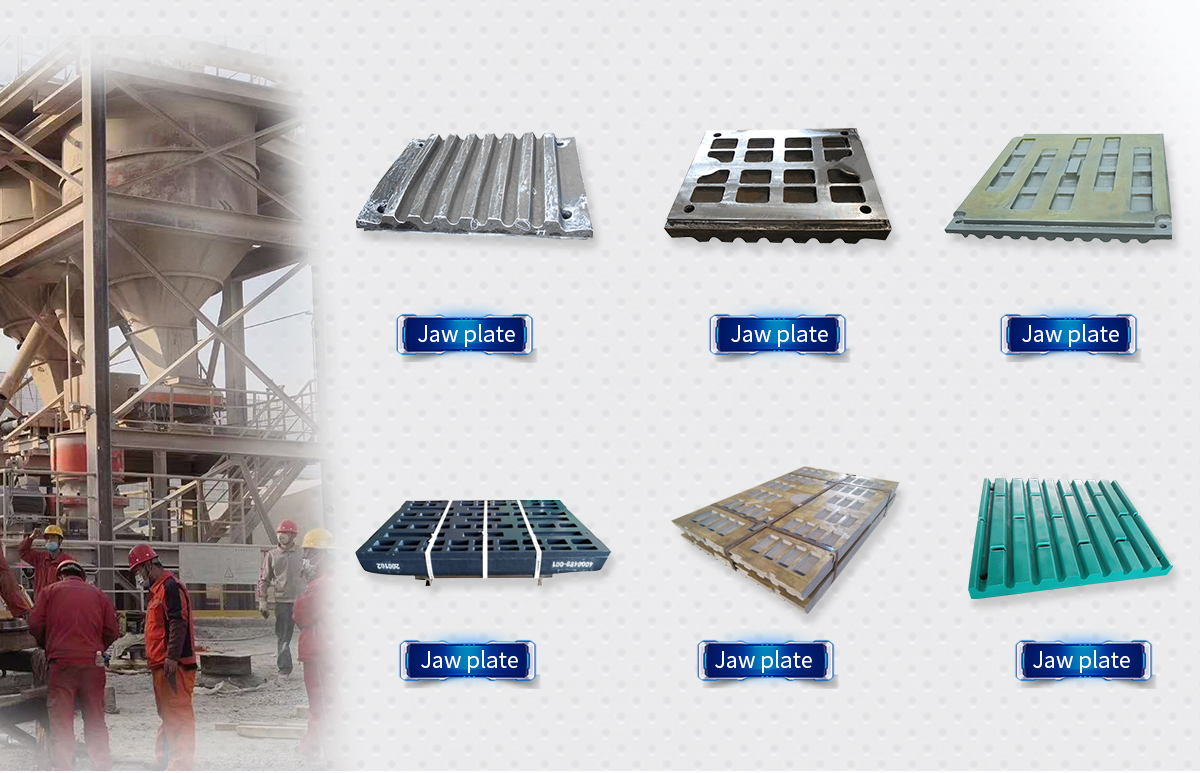

Impact crusher is important equipment in concrete production, road-building and construction waste recycle.The main spare parts are blow bar and liner plate. Our blow bars and impact plate employ the external refining technology effectively reduced the harmful elements, inpurity, oxygen and hydrogen harm, greatly enhanced the abrasion resistance and impact toughness of the steel. Using proprietary metamorphic agent for modification treatment, fine grains, improve carbide configuration and distribution, and to improves the abrasion resistance and tenacity. After heat-treatment process, the hardness of TOUGHING blow bar can reach to HRC58-63.

We always have an extensive range of after market parts for most Impact crushers,including hammers,blowbars,impact plates and side liners.

Our 27%chrome white iron and manganese wear parts are of the highest quality and have been known and proven to consistently out last and out perform any other products on the market today, we do not compromise quality with price and will find our parts to be very competitive.

All manufacturer names, numbers, symbols and descriptions are used for reference purposes only. All parts are manufactured by, for and warranted by CRUSHER SPARES and are not manufactured by, purchased from or warranted by the original equipment manufacturer.

Categories: Blow Bar, Impact Crusher Wear Spare Parts